AI-enabled operational intelligence for ensuring workplace safety

AI- powered operational intelligence can save human lives by providing timely alerts and automated actions.

In a recent unfortunate incident, nine workers lost their lives after a hydroelectric plant caught fire due to a short circuit. Such operational hazards can be effectively prevented with continuous monitoring of the operational data and AI-enabled automation to ensure that the timely action that can save human lives. The digital revolution can play a vital role in employee safety in industrial operations.

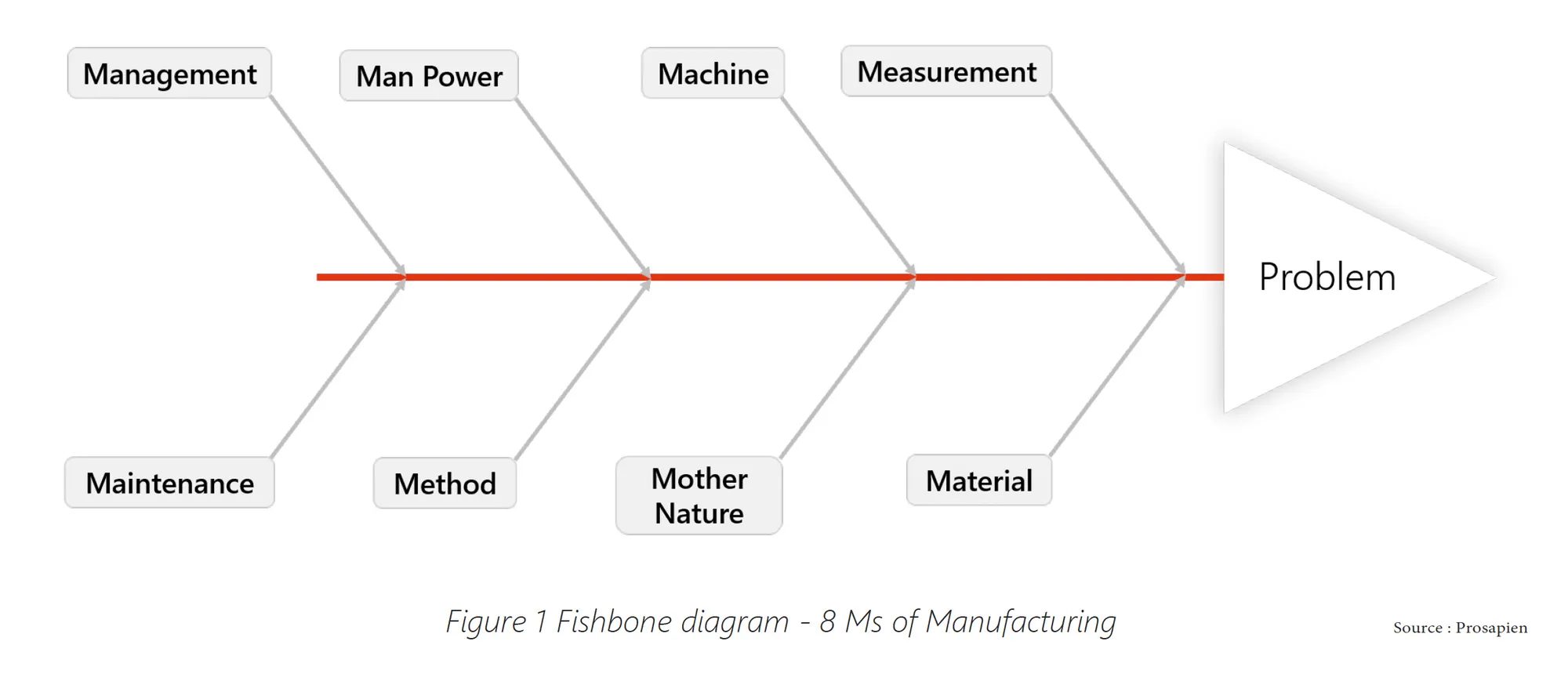

In most operational disasters, cause-and-effect diagram or Ishikawa diagram is used to determine factors of an incident and discovering actions to avoid similar incidents in the future. For example for any manufacturing incident, 8Ms of manufacturing usually play a role – Measurement, Material, Machine, Mother nature, Manpower, Method, Management, and Maintenance.

Finding the right root cause can help in discovering inherent issues prevailing in the systems, machines, and processes. With the discovered root cause, the corresponding KPIs can be tracked and automated workflows can be implemented in the digital ecosystem of industrial organizations. However, the automated workflows require advanced analytics involving extensive training of several machine learning models with large-volume data sets. AI-driven machine learning models can enable the following methods that play a crucial role in setting the safety-related workflows.

How can Eugenie help in preventing operational incidents?

Real-time asset-health-and-condition monitoring

IoT-enabled sensor technology can capture extensive information about production, asset performance, safety systems, motion monitoring, automated stoppage codes, etc. With the smart connected assets of the industry 4.0 systems, operations, and maintenance staff can get holistic visibility of the operational performance.

Eugenie is an advanced analytics solution, having a robust framework of Spot, Explore and Exploit TM that can detect operational anomalies in real-time and generate alerts that can notify the operation team with correct actionable insights. Such insights can act as a crucial input in taking the right and timely action.

Predictive risk and vulnerability analytics

The vast amount of industrial operational data such as asset performance can be merged with the incident data to identify probable operational risks and setting effective mitigation workflows by utilizing predictive insights. By accurately monitoring assets and performing proactive maintenance actions, incident rates can be significantly reduced.

Eugenie’s three-step method of Connect, Track, and Diagnose produces root-cause of any operational anomalies. Also, real-time alerts of Eugenie can assist in taking preemptive actions to avoid unforeseen incidents and ensure improved safety. At Eugenie, we implement the agile approach of operational decision making that allows better integration of cross-functional teams to ensure transparency and collaboration. With Eugenie, operational analysts can register feedbacks of the alerts and insights that can improve the efficiency of the data-based models.

Automation

In critical conditions, automated actions should be performed to prevent dangerous incidents that require the right collaboration of human decision-making and digital automation. Depending upon the operational feasibility, automation (last-mile action delegation) can also be enabled to fasten decision making that can result in preventing plant failures and detecting and safety-related issues.

Real-time operational data of the AI-enabled systems like Eugenie can be mapped with the operational expertise of the frontline staff. Eugenie’s data-driven insights and root cause analysis can help organizations to formulate actionable insights that can be digitally stored. This human-machine association can help in saving knowledge of resolution, turnaround time, recurring conditions, actions are taken to form a solution repository that can strengthen Eugenie’s machine learning models. Long-term value capture can be ensured through a robust combination of data, technology, and human cognizance.

An Altered approach to risk management

Eugenie.ai incorporates technologies such as IoT, AI, and big data analytics to make complex operational processes more efficient and reliable. Eugenie uses its powerful AI workbench to detect any anomaly and associated root causes in real-time by mining historical patterns from the data. Eugenie’s automated alert engine then notifies operation and maintenance teams to act on such insights to prevent the probable operational disaster. Eugenie further guides maintenance teams to identify corrective standard operating procedures via its automated guided simulation features to run the operation more efficiently and effectively.

For ensuring better workplace safety, the need of the hour is the system that can detect probable threats and errors in real-time and also alert operational staff for timely intervention, resulting in preventing serious damages to human lives, machines, and operational assets.

To learn more about Eugenie’s AI-driven operational intelligence solution, contact us.