Digital Twin: An essential ally in digital strategy

Using digital twins, companies can drastically improve the quality of the products and efficiency of operations.

Achieving digital transformation with Digital Twins

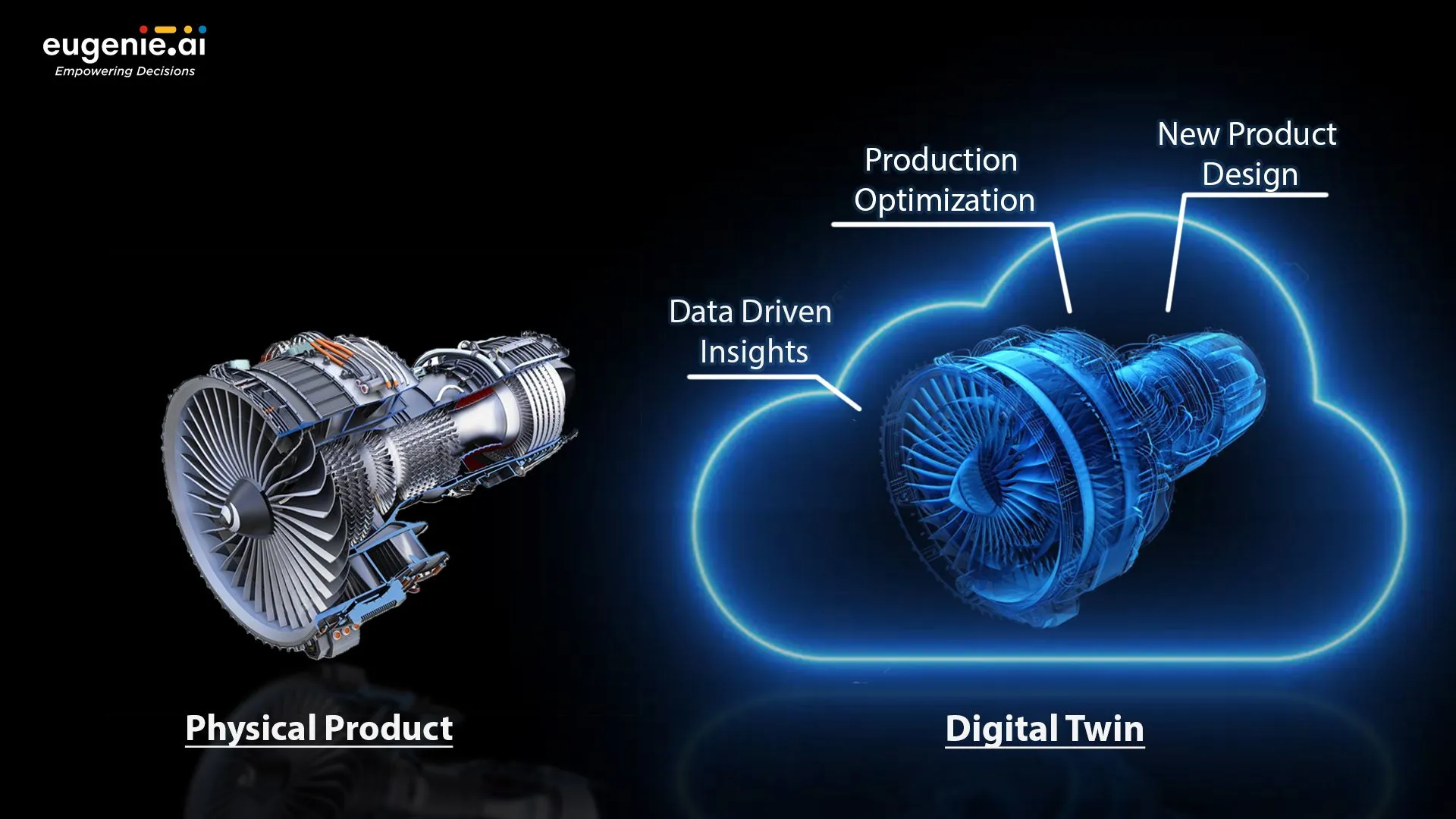

A digital twin is a digital replica of a physical asset, process or service. It connects the physical and digital world. Digital twins are enormously empowering as they enable monitoring and analysis of data and systems to predict issues before they occur in the physical world. This helps in preventing downtimes and effective resource planning for the future.

Digital twins enable simulations that can be utilized in identifying hazards and damages to the physical assets which can result in saving costs as well as in enhancing the security of citizens. Digital twins also generate a better quality of data that helps in taking more accurate business decisions as Greg Bently, CEO of Bentley Systems stated, “Digital twins lead to better quality data and in turn better management and maintenance of assets.”

Digital twins have the potential to provide a safer life for citizens, sustainable development, and better planning in the cities. By providing an accessible platform to connect information and insights, digital twins empower stakeholders to foresee scenarios and take necessary preventive measures in the construction project lifecycles. This can lead to creating a safe and reliable infrastructure in the real world.

Infrastructure creators are more and more turning towards artificial intelligence, analytics, and machine learning for leveraging simulations for creating data-driven decision support systems that can add value in operations, design, construction of physical assets.

How does a digital twin work?

Smart components that gather real-time data through sensors form the core of a digital twin. The connected devices are then attached to a cloud system that receives and analyzes the sensor data streams. With the inflow of data that gives information about operation conditions and changes over time, different business scenarios can be analyzed, and preventive insights can be generated. The insights can empower decision-makers in forming what-if scenarios that help in building reliable physical assets.

The advantages of creating digital twins are myriad and utilizing this feature is increasingly becoming popular in domains like manufacturing and construction. Here are the approaches where digital twins can be utilized.

- Designing new products

Digital twins can be used to test product performance which is functioning in real-time. This bridge between virtual and digital can enable an analysis of how a product would perform in various conditions. The benefit of this approach is the reduced complexity which is often encountered in the design of new products. This also removes the necessity of creating multiple iterations of the products – which results in saving time and operational costs.

- Optimizing production

A digital twin can help in testing the manufacturing process before the actual operations can take place. Through simulation, different processes can be tested in terms of the estimated and expected outcomes. This can contribute to optimizing production for different types of equipment by preventing downtimes as well as identifying the need for preventive maintenance.

- Generating data-driven insights

Smart manufacturing plants usually produce massive quantities of data which can enable a digital twin to generate actionable insights for accurate decision-making. By leveraging the manufacturing data, companies can improve the current production processes and generate new business opportunities.

Using digital twins, companies can drastically improve the quality of the products and efficiency of operations.